I. Precision ceramic arm main features

- Low density and high hardness and.

- Good wear resistance as well as good heat resistance.

- Excellent mechanical strength.

- Temperature environment.

- More resistant to corrosion.

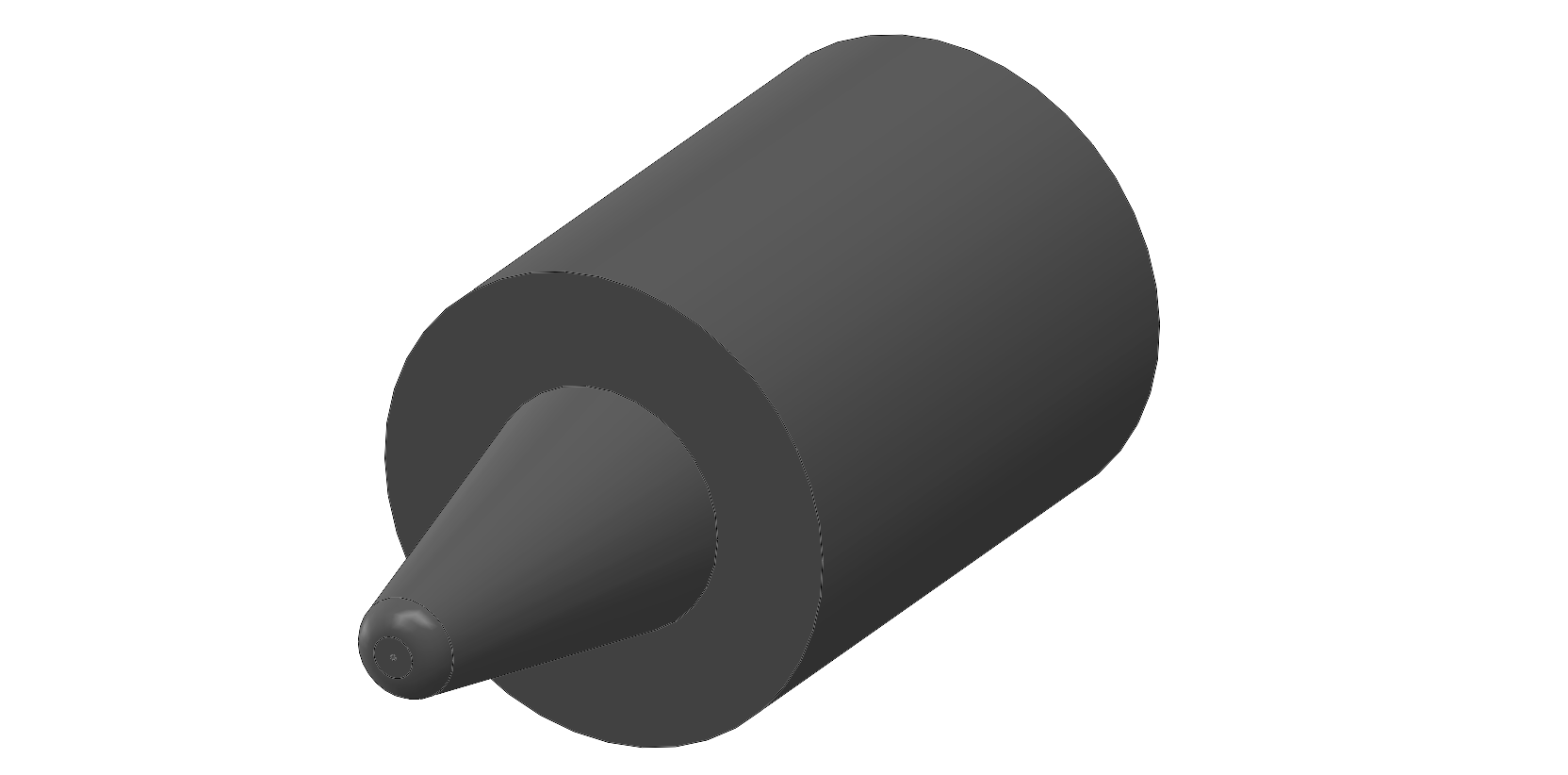

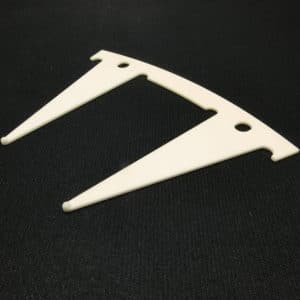

II. Product description for precision ceramic arm

The ceramic arm of the semiconductor device is used to transport the ground contact of the semiconductor device.

The precision ceramic components have good structural strength against high temperature and high pressure environment and use professional grinding equipment and post-processing to make the appearance tolerance more precise than traditional processing methods.

The appearance surface is excellent in parallelism, the internal material is evenly organized, and the external strength is high. It has been used in various semiconductor manufacturing plants for many years.

III. Material properties

✦. hardness

Rockwell hardness is HRA80-90, hardness is second only to diamond; far exceeds the wear resistance of wear-resistant steel and stainless steel.

✦. Excellent wear resistance

According to the professional research institute, its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high chromium bismuth. Based on our customer tracking survey for more than a decade, it can extend the life of the equipment by at least ten times under the same working conditions.

✦. Light weight

The alumina ceramic density is 3.5g / cm3, which is only half of the steel, which can greatly reduce the equipment load.

Zirconia ceramics have excellent wear resistance and chemical resistance. With high temperature resistance and resistance insulation properties.

Excellent thermal insulation properties and high toughness and thermal expansion coefficient close to steel.

Due to its small particle size, nano-alumina can be used to make artificial gemstones, analytical reagents and nanoscale catalysts and supports.

It can greatly improve the luminous intensity of the luminescent material and is higher than ceramics and rubber. Many times, especially to improve the compactness, smoothness, thermal fatigue of ceramics.

Nano-alumina is mainly used for the main components of YGA laser crystals and integrated circuit substrates, and is used in coatings to improve wear resistance.

IV. Custom made process ➤➤➤

- Provide customized requirements (quantity, material, size)

- Sample production (payment of sample fee)

- Quality inspection (quality control after sample preparation)

- Parcel delivery (payment of sample payment before shipment)

- Specification production (material preparation, production)