From Design to Manufacturing

Medical-Grade Ceramic Materials

Redefining Industrial Standards

Lighter, Stronger, and More Durable

Affordable Excellence, Delivered Fast with Integrity.

Advanced Ceramic Overview

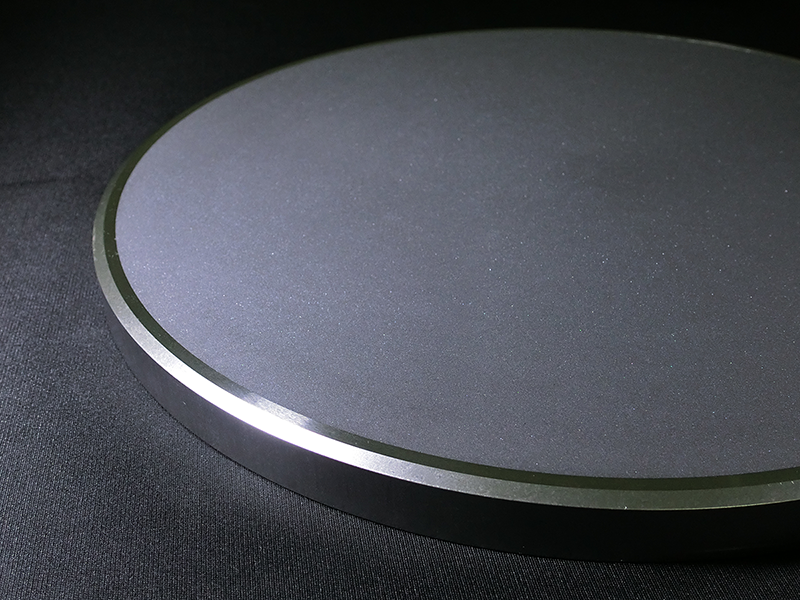

Advanced ceramics, also known as technical ceramics or engineered ceramics, are specialized materials with superior properties. These materials are developed from traditional ceramics to deliver enhanced thermal and mechanical performance. Their unique features include exceptional wear resistance, low thermal expansion, excellent thermal stability, and remarkable corrosion resistance.

Unlike traditional ceramics, advanced ceramics are widely applied in industries such as semiconductors, optoelectronic packaging, aerospace propulsion, power generation, and industrial equipment. Their high-performance characteristics make them indispensable in solving complex engineering challenges.

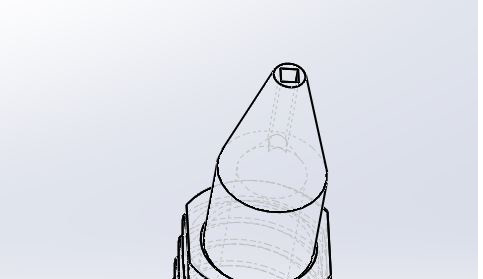

Key Features of Advanced Ceramic

Thermal Properties: Advanced ceramics exhibit outstanding thermal stability and resistance to extreme temperatures.

Durability: These materials offer long-lasting wear resistance, even under harsh conditions.

Corrosion Resistance: Engineered ceramics resist chemical degradation, ensuring reliability in corrosive environments.

Low Dielectric Constant: Ideal for electronic applications, they minimize energy loss.

Mechanical Strength: Advanced ceramics maintain structural integrity under high stress.

Applications of Technical Ceramic

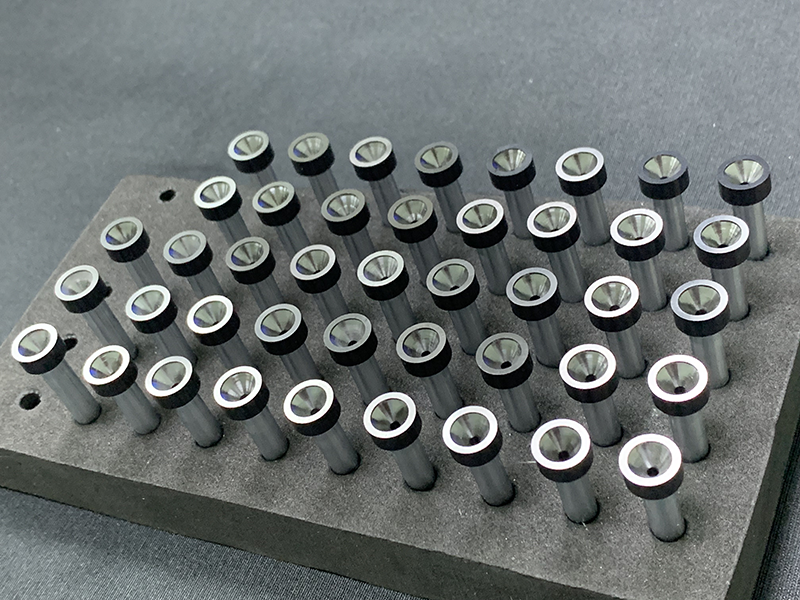

Semiconductors: Used in high-precision components for electronic devices.

Optoelectronics: Essential for packaging and protecting sensitive optical systems.

Aerospace: Critical in propulsion systems for their lightweight and heat-resistant properties.

Industrial Equipment: Enhance performance and longevity of machinery in demanding environments.

Why Choose Engineered Ceramic?

Engineered ceramics deliver unmatched performance in specific applications. Their ability to withstand extreme conditions ensures reliability and efficiency. These materials are essential for industries requiring high-performance solutions.

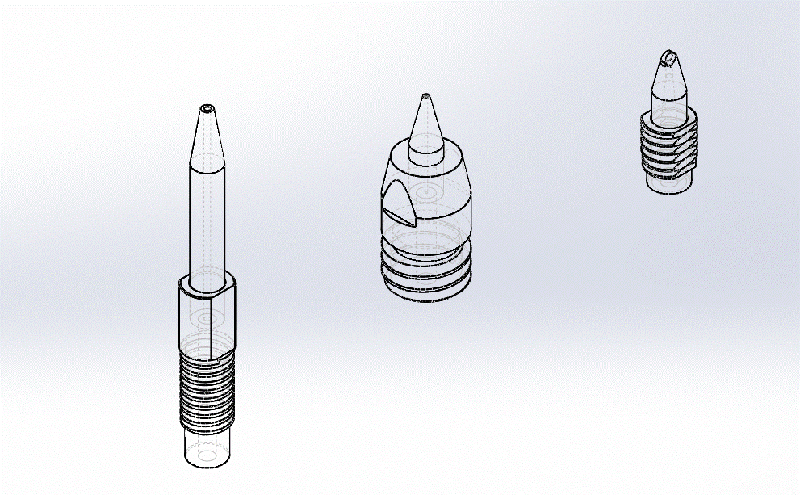

The Most Advantageous Product

Why Choose Us?

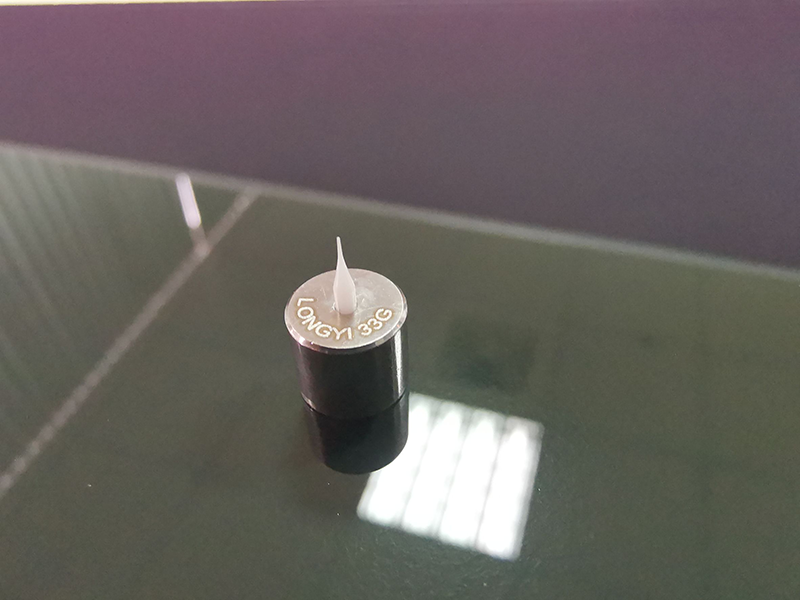

LONGYI focuses on quality. It is the main feature of LONGYI to provide customers with measurement reports before shipment, and the report files are directly output to PDF files by the measurement system. The measurement report includes distance tolerance, flatness, parallelism, perpendicularity, and coaxiality.

2.5D image measurement Main features:

1.Accuracy 0.001mmMaximum stroke 1100*600mmMaximum magnification 200X (0.03mm hole can be measured)

2.It can coordinate with the probe, calculate the measurement data and the same report.

We want you to be our next satisfied customer

Conscientious on details

Longyi is committed to providing the best quality in the precision technology industry. Our production process is strictly inspected, and our materials are carefully selected.

Pursuit of excellence

We strive to better the internal processes and improve production efficiency to enhance our customer satisfaction, which has eared positive responses and feedbacks from our customers worldwide

Quick delivery and considerate service

Professional quality productions enable us to produce the maximum result in the shortest time. Our powerful manufacture offers large capacity and ensures stable and short lead time.