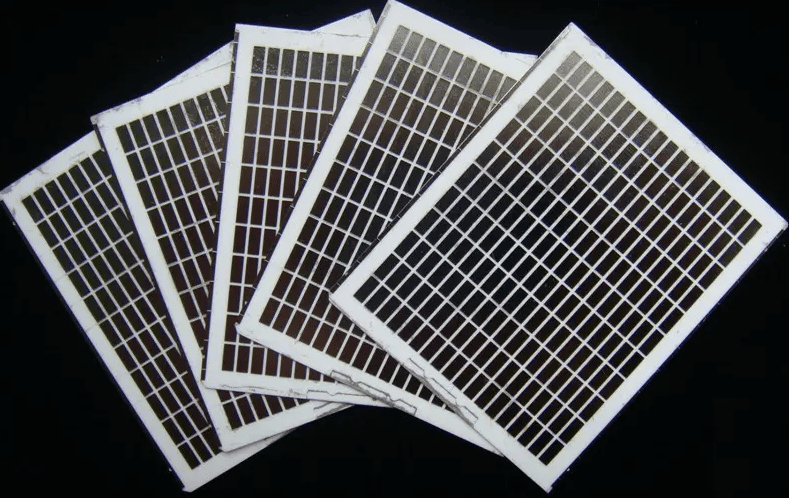

CERAMIC METALLIZATION

Advanced ceramic has distinctive properties, thus it can be joined with metals. Before joining with metal the ceramic needs to be metalized (thin-coating it with metal material which provides an interface for brazing). Then brazed, which creates a vacuum tight, robust joint between ceramic and metal.

LONGYI specialize in cutting-edge ceramic metallization solutions that redefine the possibilities of material engineering. With a commitment to innovation, precision, and quality, we bring decades of experience to the table. Our team of experts is dedicated to pushing the boundaries of ceramic technology, providing customized solutions for diverse industries.

CERAMIC THAT’S OFTEN METALIZED

Alumina (Al2O3), because of its electrical insulation, high thermal conductivity, high chemical resistance, good wear resistance and low thermal expansion.

Aluminum Nitride (AlN), because of its thermal conductivity, thermal expansion coefficient, and electrical insulation.

HOW IS IT METALIZED?

With our technology, we utilize Moly-Manganese formula as coatings to make a strong bond with brazing agents.

After applying the ink formula,in a hydrogen/nitrogen controlled atmosphere, they are fired at a temperature of 1300 to 1500°C.

APPLICATIONS

High voltage ceramic plates

Vacuum electron devices

Bio-compatible implantable devices

Lasers

Available Ceramic Compositions Al2O3 94%, 96%,

Metallization Materials Mo/Mn

Metallization Thickness 25um ±10um

Customized Solutions

Our team understands that every project is unique. Collaborate with us to create tailored ceramic metallization solutions that meet your specific requirements. From prototype development to large-scale production, we are committed to delivering results that exceed expectations.