CERAMIC NOZZLE | ceramic capillary

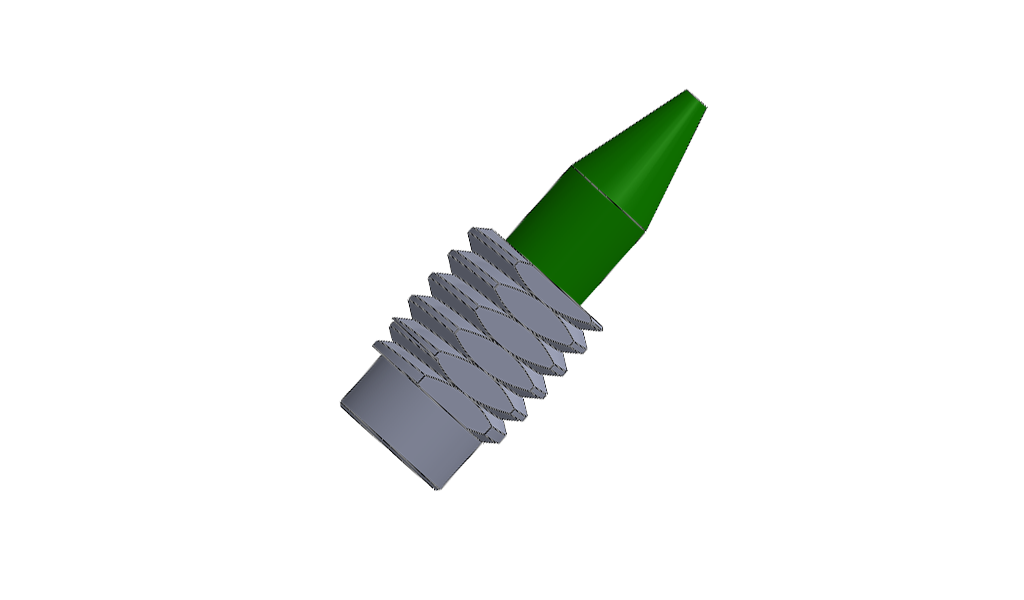

There are many types of ceramic nozzles, which can be roughly divided into dispensing series and pick and place series.

LONGYI focuses on the adhesive dispensing series. We produce ceramic and stainless steel dispensing needles, that’s unlike the general metal products on the market.

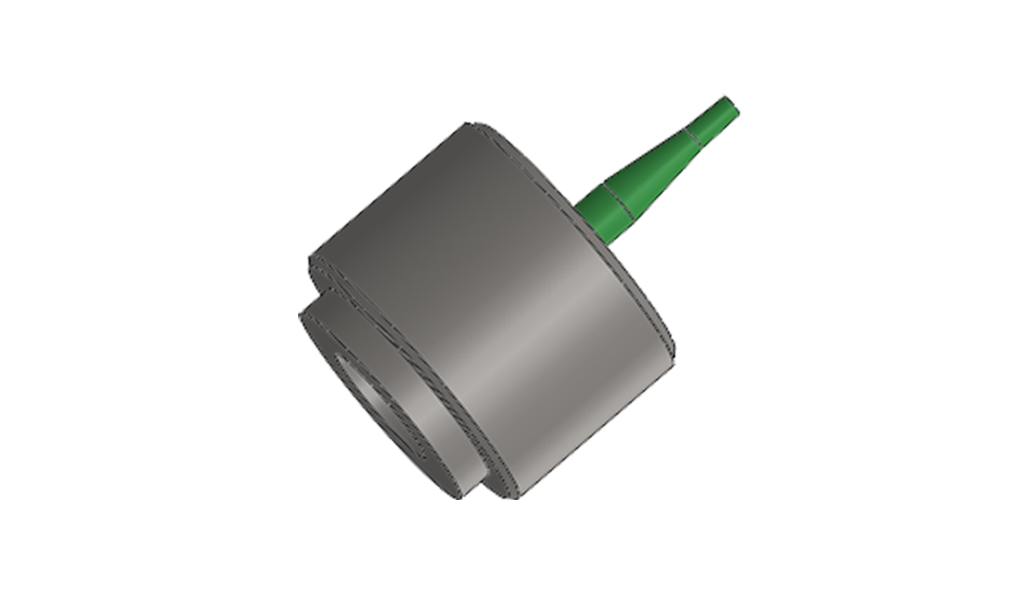

FEATURES

Smooth inner diameter that makes adhesive agents flow steadily.

Hardness (HR80-90), more abrasion resistant than metals.

Easy to clean inner surface

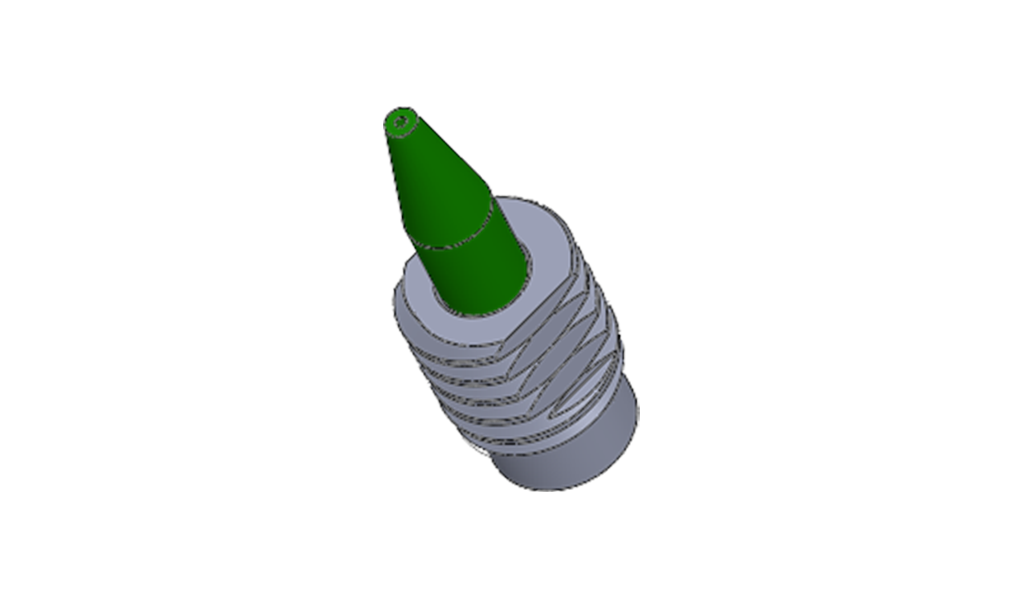

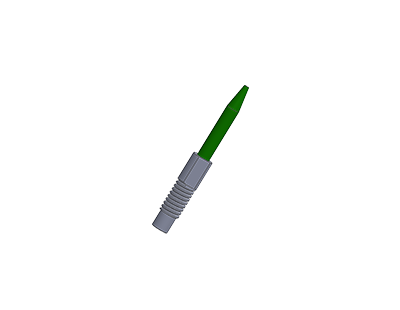

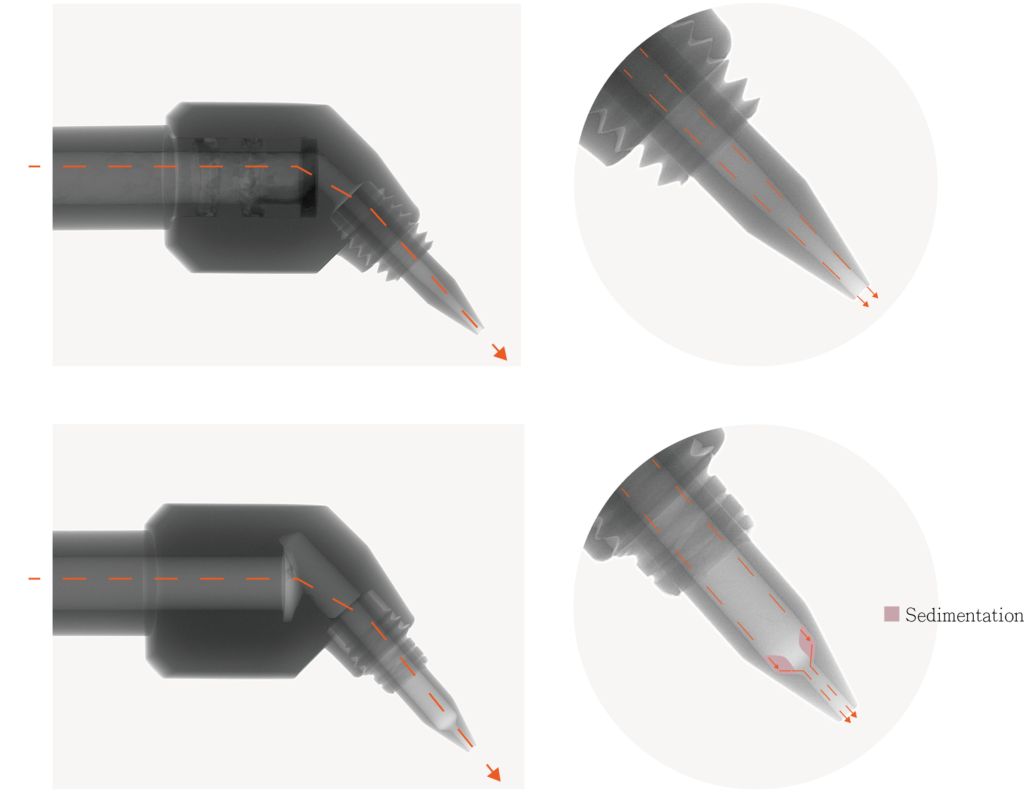

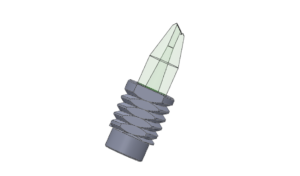

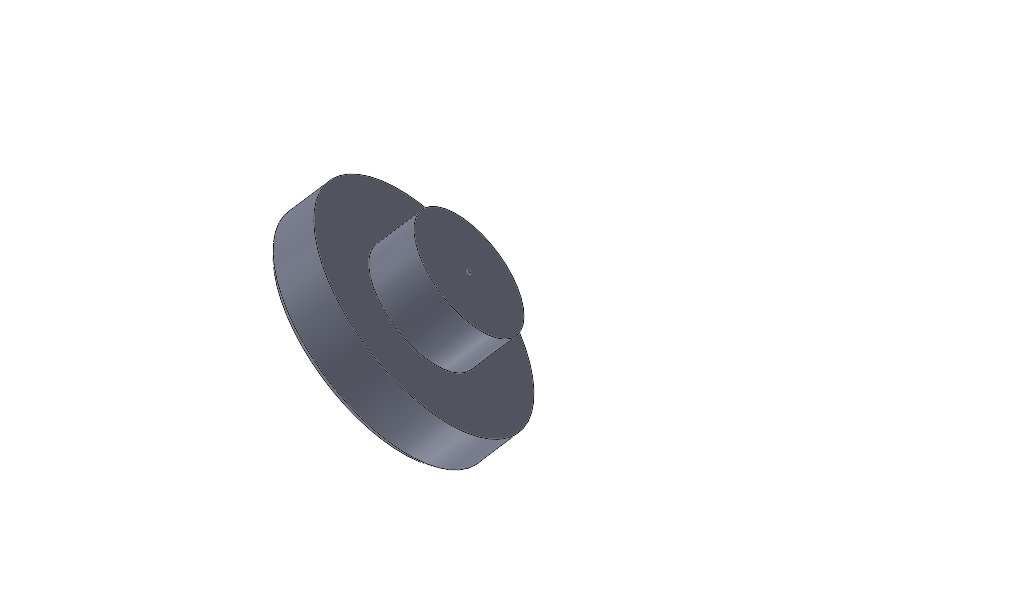

DETAILS

We make our nozzle’s inner shape as straight as it can be so it won’t have any sedimentations unlike other brand’s. That’s why LONGYI dispensing nozzles have a better lifetime.

specification

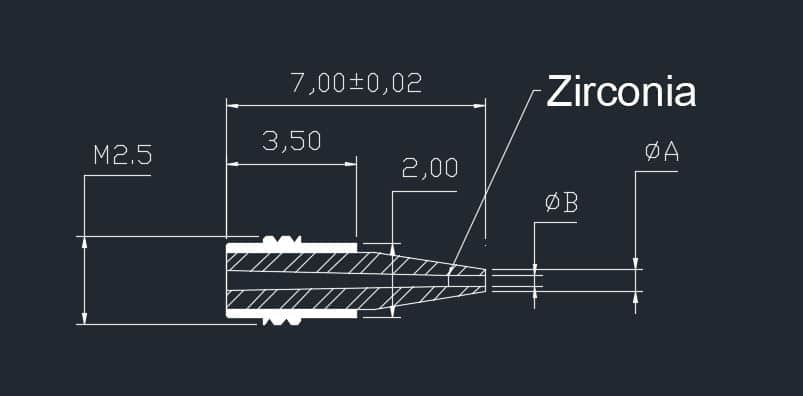

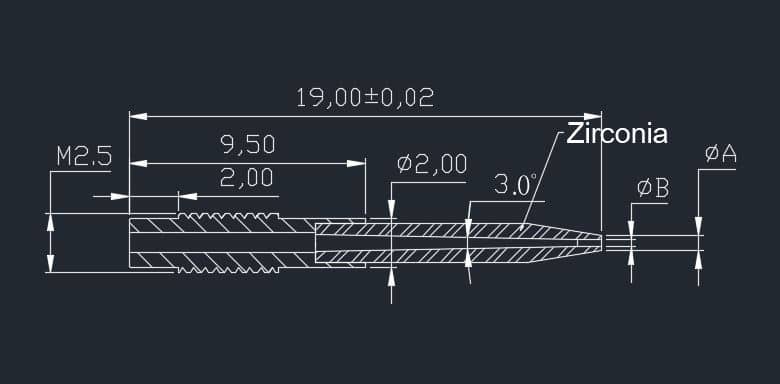

Our ceramic nozzle can be customized.

First, we make the inner diameter then we make the outer shape.

Through the machining process we can provide the utmost precision outcome (tolerance 0.05).

differences

Ceramic glue needle is glued at a speed of 90%

Tungsten steel needle output speed is 90%

Tungsten steel needle output speed is 50%

Tungsten steel vs ceramic

When the tungsten steel nozzle dispenses glue at 90% speed, it shows an inconsistent amount of glue, making the product prone to fail QC. As shown above, Tungsten steel needs to slow down (to 50%) for its result to be the same as ceramic nozzle at 90% speed.

In conclusion, Using ceramic nozzles will cut down the dispensing glue time by 40% with a great end result.

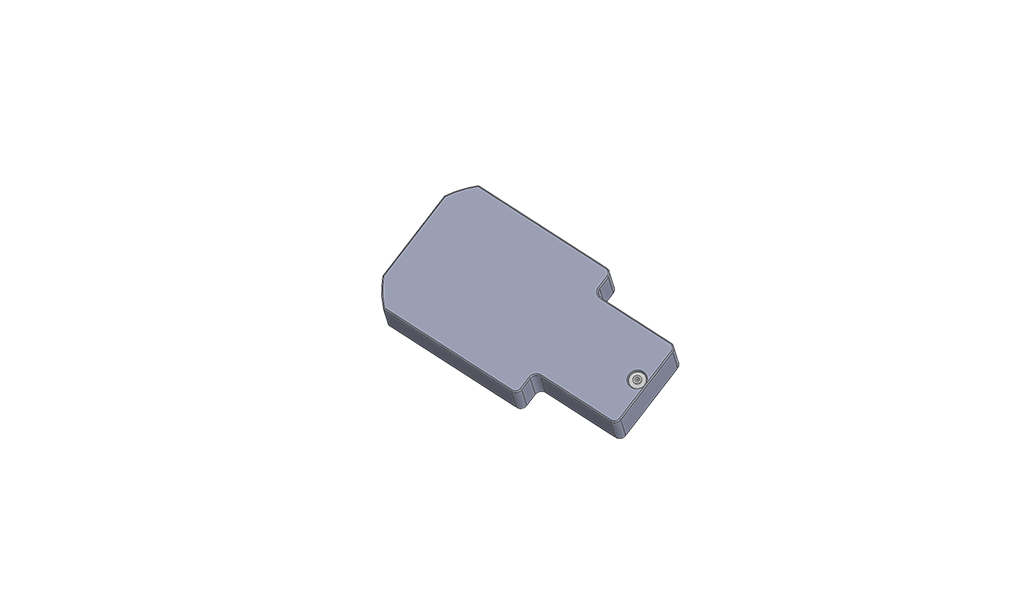

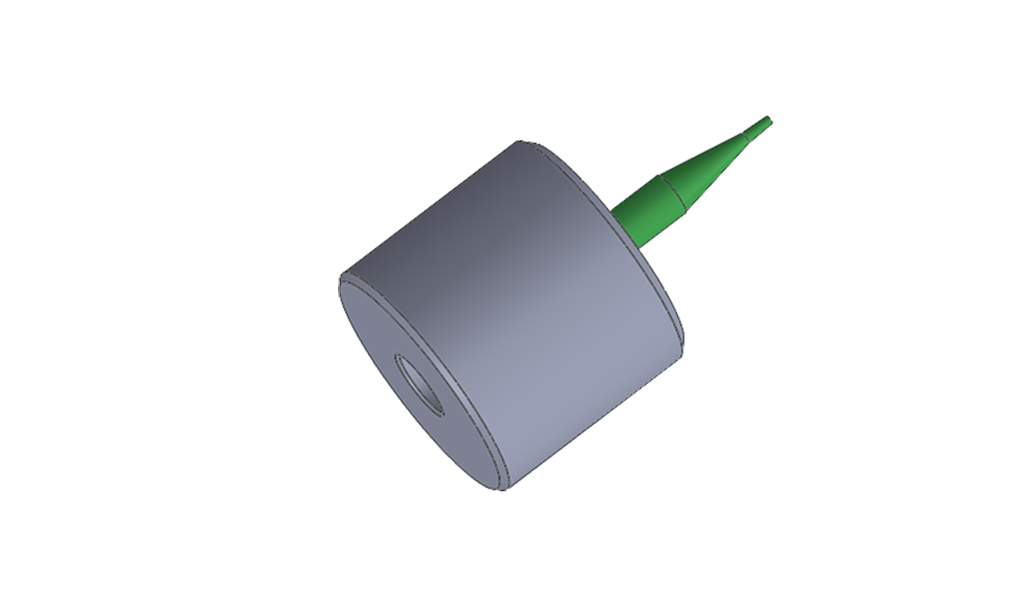

OUR PRODUCTS

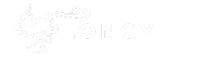

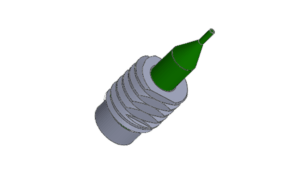

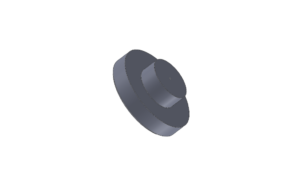

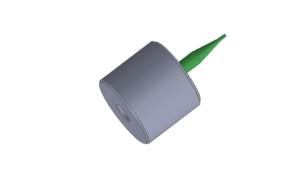

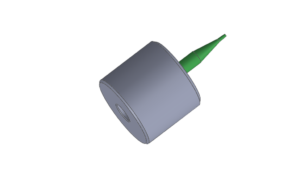

7L EPOXY DISPENSING NOZZLE

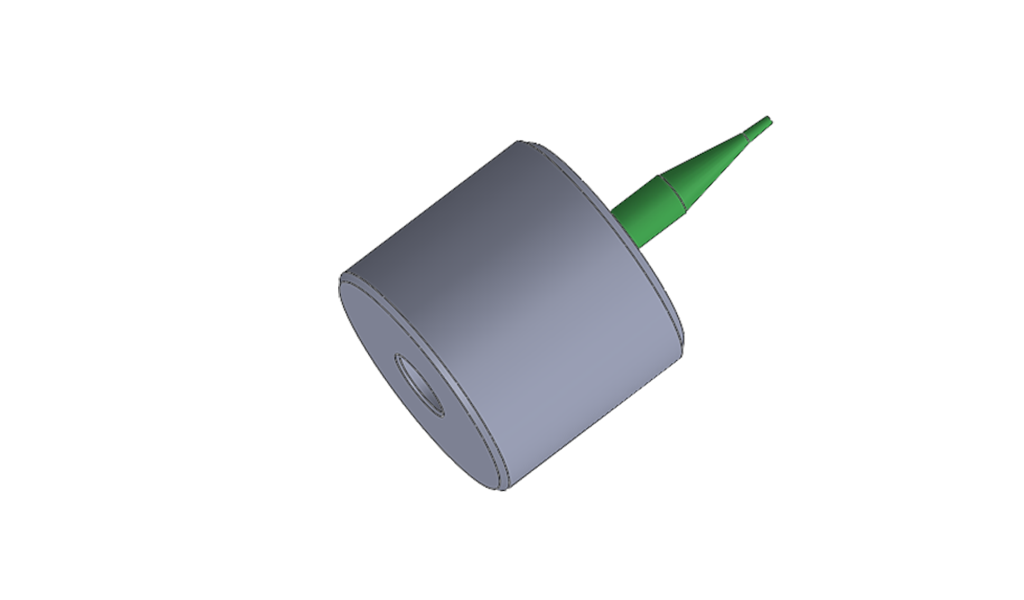

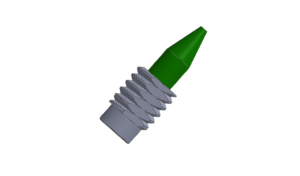

EPOXY DISPENSING NOZZLE -ZRO-QS-07

EPOXY DISPENSING NOZZLE 04-V

EPOXY DISPENSING NOZZLE – C01088856-N

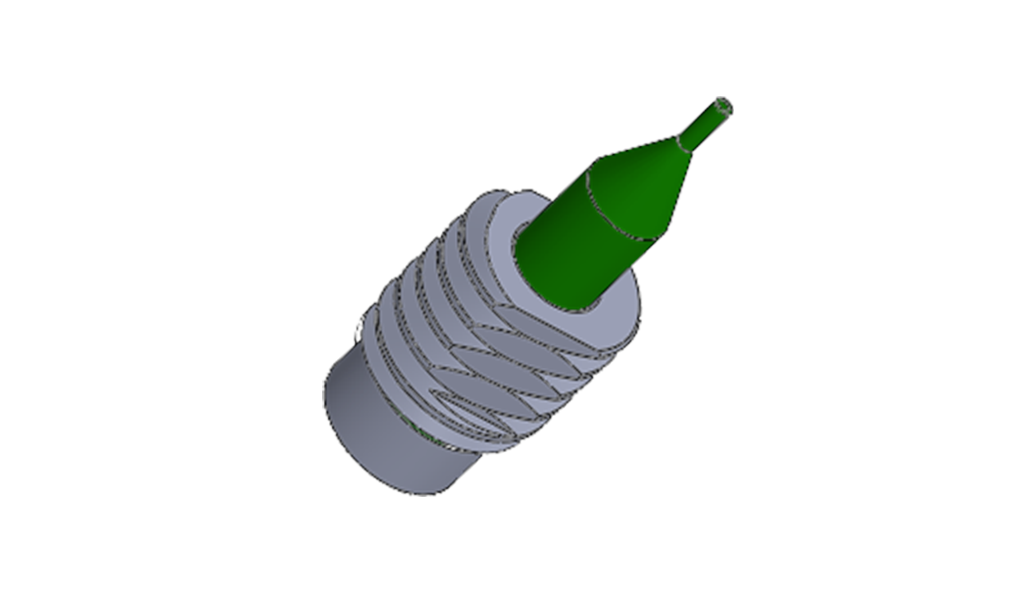

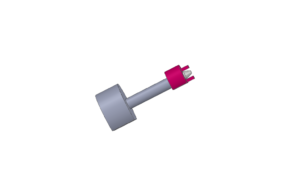

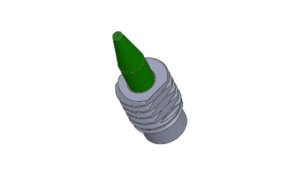

EPOXY DISPENSING NOZZLE – INSERT QUILL – SCPC

EPOXY DISPENSING NOZZLE – KL-06

EPOXY DISPENSING NOZZLE – V04D

EPOXY DISPENSING NOZZLE – ECZ05

EPOXY DISPENSING NOZZLE – C01088856

EPOXY DISPENSING NOZZLE – DL2P

Epoxy Dispensing Nozzle11.95L-G

EPOXY DISPENSING NOZZLE – GF2

EPOXY DISPENSING NOZZLE – 7A

7L EPOXY DISPENSING NOZZLE

7L Epoxy Dispensing Nozzle

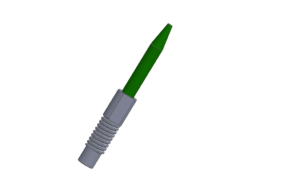

EPOXY DISPENSING NOZZLE – INSERT QUILL – 304222

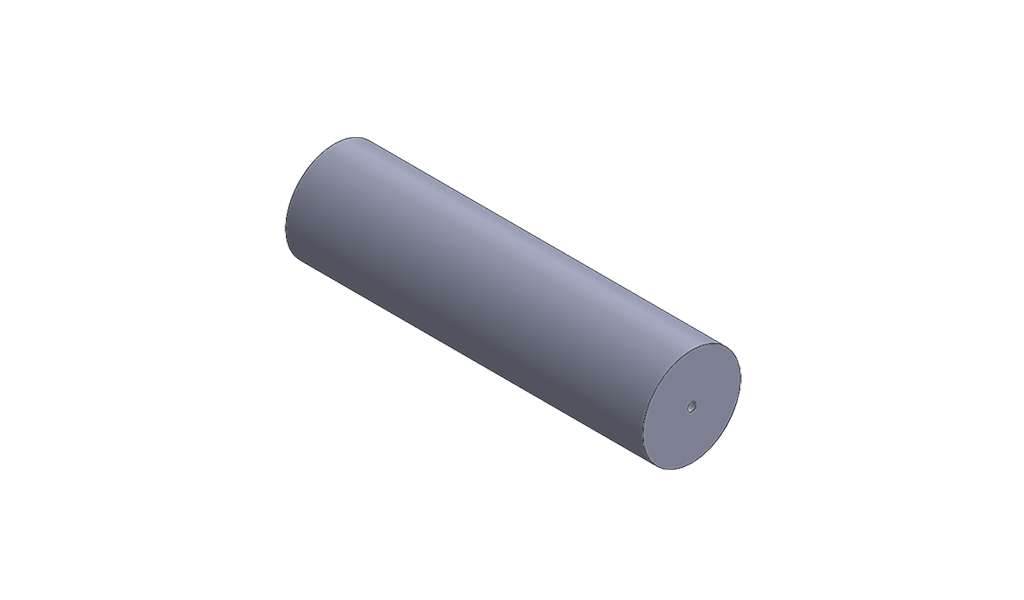

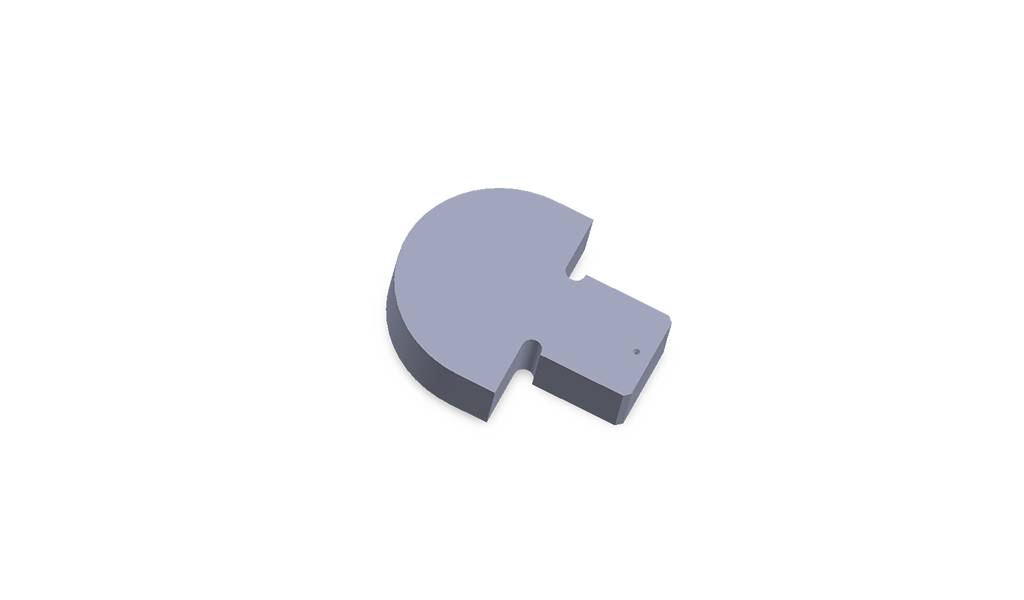

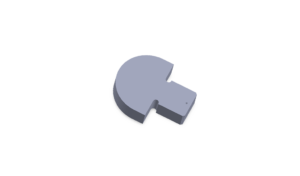

pick and place nozzle

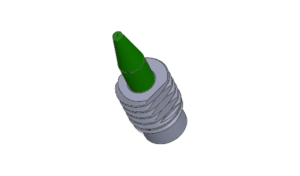

From the development to this day, from steel to insulating plastics to special ceramic nozzles. It replaces the previous nozzles which are made of various materials. The ceramic nozzle is made of refined zirconia at a high temperature ≥ 1230 degrees and it’s mainly black or white ceramics. These nozzles are made of imported zirconia, which is more durable and stable than its tungsten steel nozzle.

Process

Setup and prepare the Pick and place nozzle system.

Detect and locate the object to be picked up.

Use the gripper or suction cup to pick up the object.

Transport the object to the desired location.

Place the object at the target position.

Repeat the above steps in a continuous operation.

Function

Picks up objects and places them at designated locations.

Components

Gripper or suction cup, control system.

Application areas

Manufacturing, electronics assembly, packaging and logistics

Purpose

Enhance production efficiency and accuracy.