Boron Nitride (BN)

Boron Nitride (BN), as one of the hardest and hardest materials, has a wide range of industrial applications. Although BN has a lower hardness than diamond, it is widely used in cutting tools due to its high chemical and thermal stability, especially for hardened steel materials.

The misoriented interphase boundary between BN (precipitate) and SiC grains (within a silicon nitride particulate-reinforced silicon carbide composite)

Boron nitride is a binary phase composed of the same amount of nitrogen atoms and boron atoms. The boron nitride product that LONGYI made is hexagonal boron nitride. The hexagonal boron nitride’s properties and structure are similar to graphite. Hexagonal boron nitride also called h-BN, and sometimes called white graphite, is the only ceramic material that can resist 2000℃ high temperatures. At present, boron nitride is widely used in high-temperature furnaces.

Features:

Boron nitride (BN) consists of boron-nitrogen covalent bonds and is commonly used as a refractory. Isoelectrically equivalent to the Sp 2 carbon lattice, BN is often compared to allotropes.

Is a crystalline material synthesized from boric anhydride and pure low-ash carbon materials in an electric furnace at 1,800 ° C ~ 2,500 ° C (3,300 ° F ~ 4,500 ° F). Its hardness is about 3,800 HV and it has good cutting ability in the form of loose particles. However, the low oxidation temperature is 430 ° C (800 ° F)

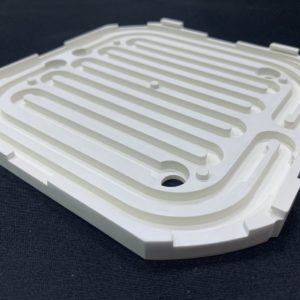

Boron Nitride (BN) products we've customized

- Alternate Names

Precision Ceramic