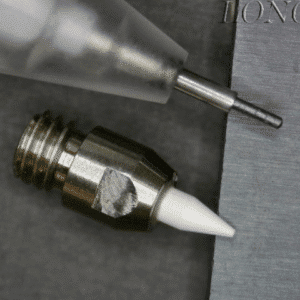

Porous Ceramic Nozzle tools

Can be classified stainless steel (main body) and Porous Ceramic pick and place tools. Porous ceramic nozzle can be divided different pore sizes (2um, 10um, 20um, 30um).The larger pore sizes will be large air flow.

Porous Ceramic are different from perforated vacuum nozzles, the main purpose is to vacuum suction soft and thin parts also no deformation.It is suitable for semiconductor chips, optical components/films and FPC.

There are two important factors in good vacuum suction parts:

1. It’s sucked parts in parallel/vertical

2. Suitable vacuum source

| Item NO./ Dim | A | A1 | Porous ceramic propertys: | ||||

| CER-PRO-NOZ-01 | 3 | 3 | Al2O3%: ~92% | Water%: 0% | |||

| CER-PRO-NOZ-02 | 3.5 | 3.5 | Porosity: 35~40% | Pore size: 10um | |||

| CER-PRO-NOZ-03 | 4 | 4 | Bending : >6 kgf/cm2 | Bulk Specific: 2.28 g/cm3 | |||

| CER-PRO-NOZ-04 | 4.5 | 4.5 | Coloring: Black | ||||

customized products :

Al2O3%: ~92% Water%: 0%

Porosity: 35~40% Pore size: 30um

Bending : >6 kgf/cm2 Bulk Specific: 2.28 g/cm3

Coloring: Black

High speed epoxy “dotting”. Widely used in industries such as IC sealing, photovoltaic, LCD, LED sealing, LED potting, computer/phone cases and frames adhesion, SMT parts, circuit board assembly etc.

Die Bonding Stamping Pin is used in the back-end process of bonding. Its functions include protecting substrate, microcircuit, IC, and preventing the possible damages from dust, moisture, light and other substances that might cause the damages of products. Can do a variety of other functions depending on what specific needs the business requires.