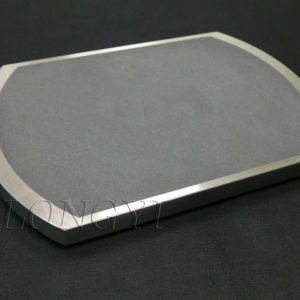

POROUS CERAMIC Vacuum Chuck

Porous ceramic KEY CHARACTERISTIC

The Porous Ceramic Vacuum Chuck effectively absorbs workpieces during the manufacturing process.

By collaborating with an air floating stage and a non-contact transfer system, the Vacuum Chuck can elevate workpieces.

pRINCIPLE

When the ceramic emits airflow outward (negative vacuum pressure), it secures the workpieces through absorption.

Conversely, when the ceramic receives inward airflow (positive vacuum pressure), it either lifts the workpieces or keeps them from making direct contact with the ceramic surface.

Vacuum nozzle, pick and place workpiece

Bonding stage, soft material bonding

Air bearing, low friction rails

Touchless glass transfer stage

Testing AOI system

applications in semicon industry

Wafer Transportation

Wafer Dicing

Laser Dicing

Wafer Grind

Wafer Cleaning

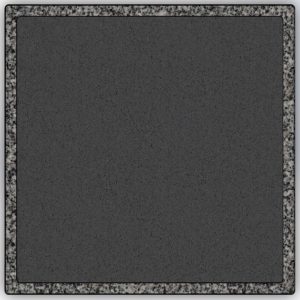

features

Secure parts that’s complex (warped, hollowed, various sizing)

Tiny pore sizes (2um) makes the surface contact traceless.

Great mechanical strength

Heat Resistance

Chemical resistance

Static dissipative

usage requirements

High precision flatness

Great Permeable

Reliable adhesive

Flat joint

Massive air flow

Large bore pipes and fittings

|

Item No. / SPEC.(mm) |

L |

W |

T |

Flatness (um) |

|

C-PRO-GB-10-10 |

100 |

100 |

29 |

0.01 |

|

C-PRO-GB-20-20 |

200 |

200 |

29 |

0.01 |

|

C-PRO-GB-30-25 |

300 |

250 |

29 |

0.02 |

|

C-PRO-GB-40-30 |

400 |

300 |

32 |

0.02 |

|

C-PRO-GB-60-30 |

600 |

300 |

35 |

0.03 |

|

C-PRO-GB-120-80 |

1200 |

800 |

60 |

0.05 |

|

C-PRO-GB-100-100 |

1000 |

1000 |

60 |

0.05 |

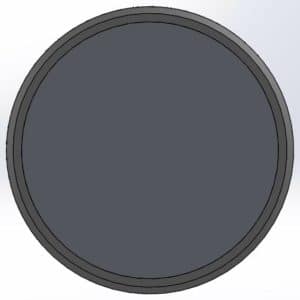

| Item No. / SPEC.(mm) | L | W | T | Net/Weight(cm) |

| CPC-SS-06 | 6 | 0.005 | 1.7 | 33X33X6 |

| CPC-SS-08 | 8 | 0.005 | 3 | 33X33X6 |

| CPC-SS-12 | 12 | 0.008 | 9.3 | 45X45X6 |