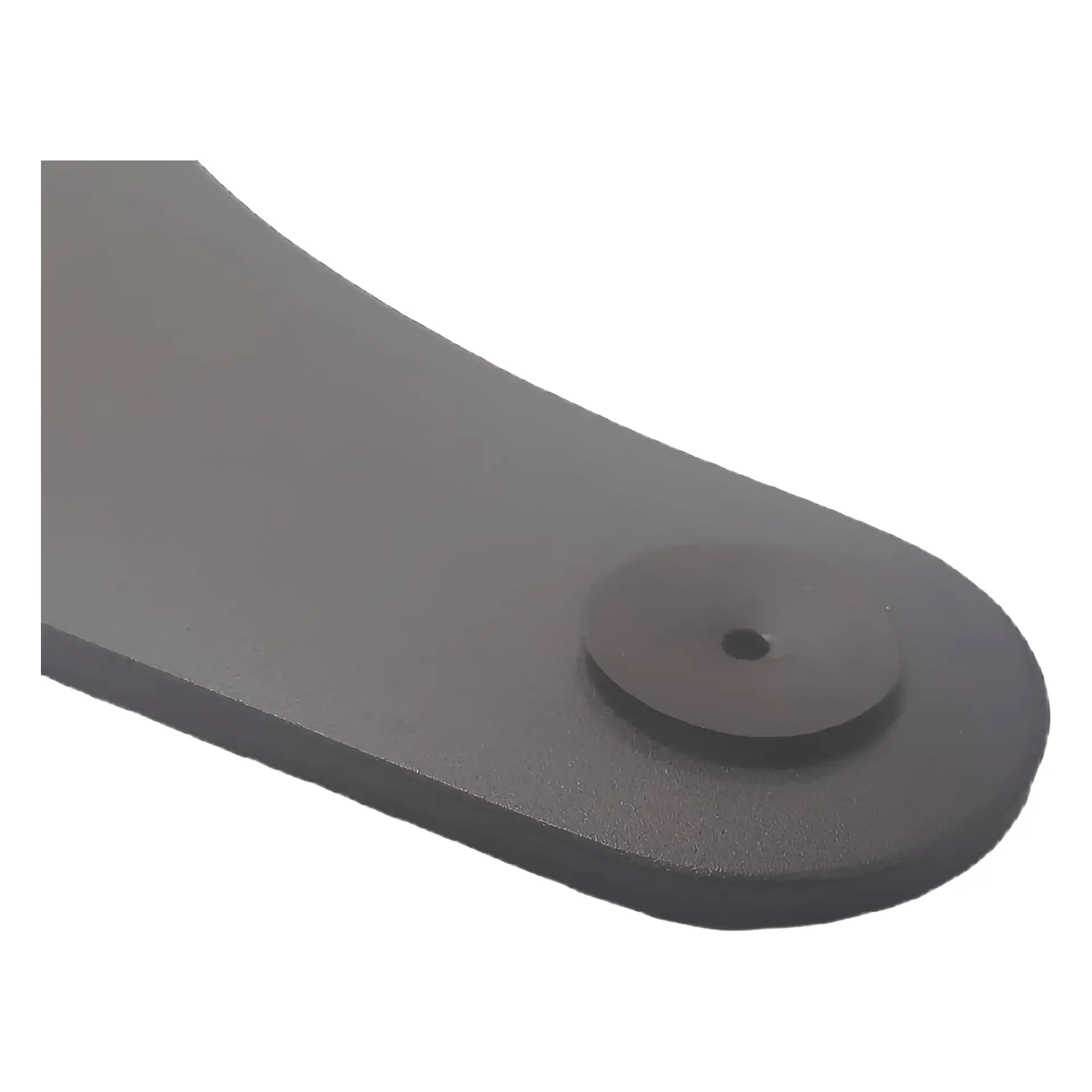

Wafer Transfer Robot Arm: The Core of Wafer Transfer Precision

The wafer transfer robot arm, also known as semiconductor robots arm or ceramic end effector, is an essential tool in the semiconductor manufacturing process. These devices ensure precise wafer handling, reducing contamination risks and improving production efficiency. From wafer cleaning to lithography, the robot arm guarantees accuracy and stability, making it indispensable for semiconductor manufacturers.

Why Ceramic Materials Are Ideal for Wafer Transfer Robot Arms

Ceramic materials, especially zirconia and high-purity alumina ceramics, are widely used in wafer transfer robot arms due to their outstanding technical properties. These materials provide the necessary strength, durability, and cleanliness required in semiconductor manufacturing.

Key Features of Alumina Ceramics

- High Purity and Antistatic Properties

Alumina ceramics with 99.7% purity and antistatic coating ensure optimal performance in cleanroom environments. - Mechanical Strength and Hardness

Alumina exhibits excellent wear resistance and dimensional stability, even under long-term use. - Low Thermal Expansion

This property ensures minimal deformation during temperature fluctuations. - Surface Quality

Advanced polishing and coating processes enhance flatness and reduce surface roughness, meeting stringent semiconductor manufacturing standards.

Superior Mechanical Performance

The wafer transfer robot arm achieves micron-level precision, thanks to its high rigidity and excellent bending resistance. This ensures stable and accurate wafer movement, even when handling wafers of various sizes and thicknesses.

Advanced Surface Treatment Technology

- Precision Grinding and Polishing

Guarantees smooth surfaces for reduced particle generation. - Antistatic Coating

Prevents electrostatic discharge (ESD) damage. - Surface Roughness Control

Ensures optimal cleanliness and precision handling.

These technologies make ceramic wafer transfer robot arms highly reliable in cleanroom environments.

Applications in Semiconductor Manufacturing

Ceramic wafer transfer robot arms are ideal for handling wafers of different specifications, including 150mm to 300mm sizes. They adapt to various materials and thicknesses, ensuring precise positioning and alignment. Their stable performance supports processes like cleaning, etching, and lithography.

Manufacturing Processes

- Precision Molding and Sintering

Delivers high dimensional accuracy. - Surface Treatment

Enhances durability and cleanliness. - Assembly Precision

Ensures reliable performance during wafer handling.

Quality Control Standards

To meet semiconductor industry demands, ceramic wafer transfer robot arms undergo rigorous testing:

- Dimensional Accuracy

Ensures flatness and parallelism within 0.03mm. - Material Testing

Verifies mechanical and thermal properties. - Dynamic Performance

Confirms stability during operation.

Customization with LONGYI

LONGYI offers tailored solutions for wafer transfer robot arms. By providing 2D-PDF and 3D-STP files, customers can receive customized designs that meet specific requirements. Materials such as Alumina 99.7%, ESD-coated ceramics, and antistatic ceramics are available to suit diverse applications.