Antistatic ceramic

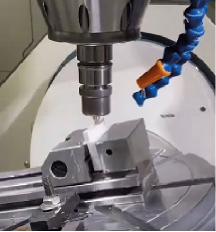

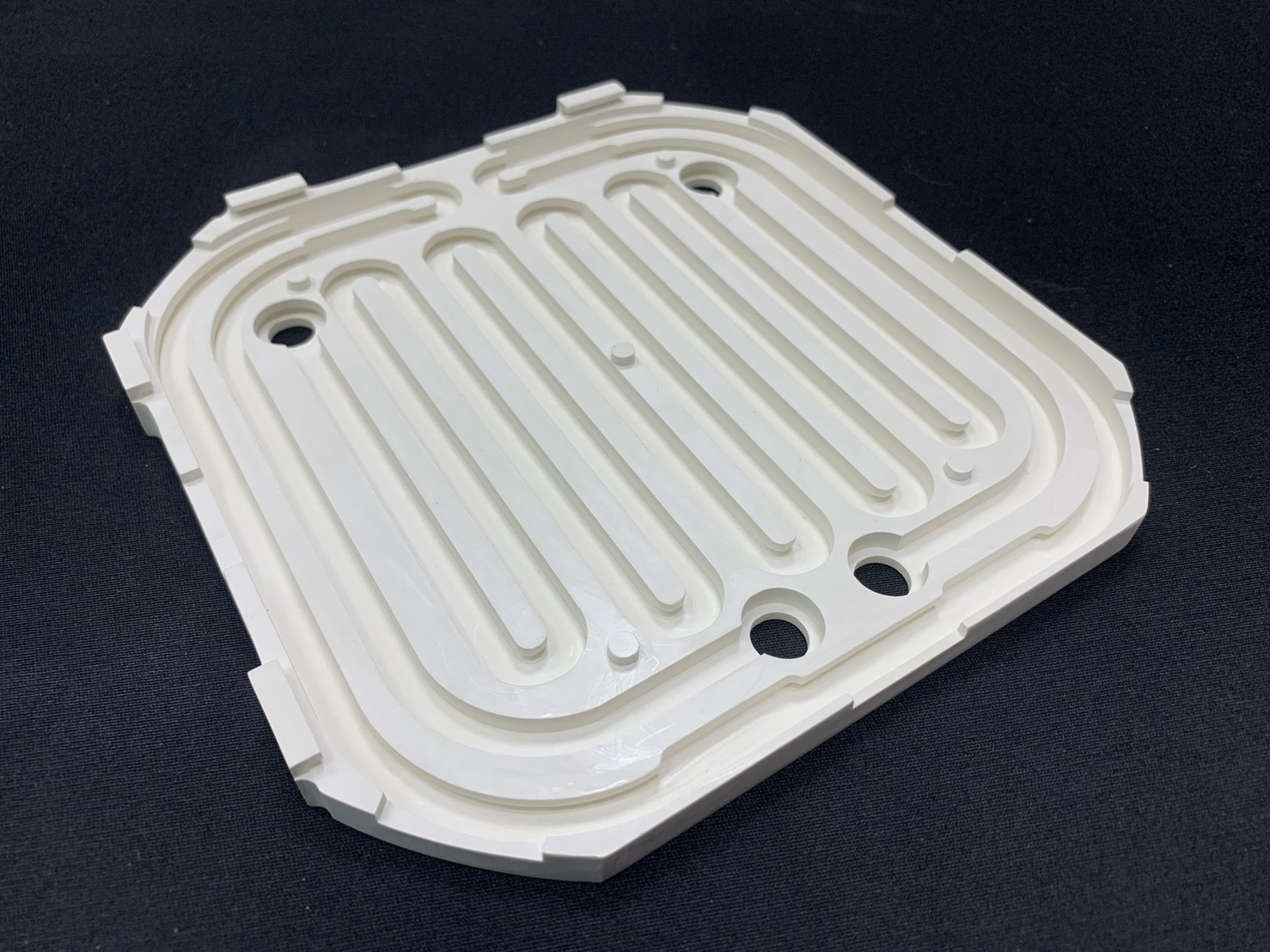

aNTISTATIC CERAMIC / ESD MATERIAL Antistatic ceramics are specially designed ceramics that dissipate or prevent the build-up of static electricity. They are used to protect sensitive electronic equipm […]

Antistatic ceramic Read More »