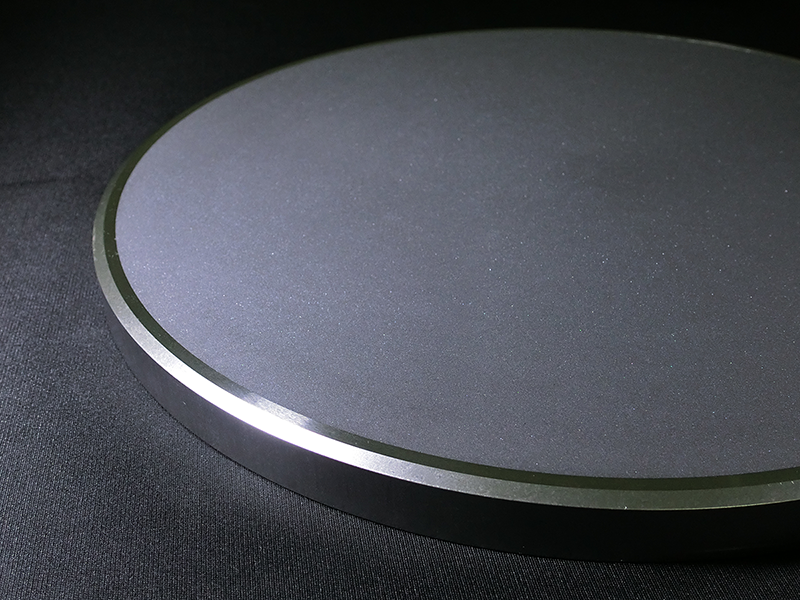

Antistatic Porous Ceramic with SGS Certification

Antistatic Porous Ceramic with SGS Certification LONGYI proudly announces the successful development of Antistatic porous ceramic in collaboration with our clients. This innovative material combines a […]

Antistatic Porous Ceramic with SGS Certification Read More »